In the world of mechanical systems, precise control over motion and speed is crucial for efficiency and safety. This is where electromagnetic products like electromagnetic clutches and brakes come into play. These innovative devices utilize the power of electromagnetism to enable seamless control, reliability, and safety in various industrial applications. We will explore the fascinating world of electromagnetic clutches and brakes, delving into their functions, applications, advantages, and their significance in modern engineering.

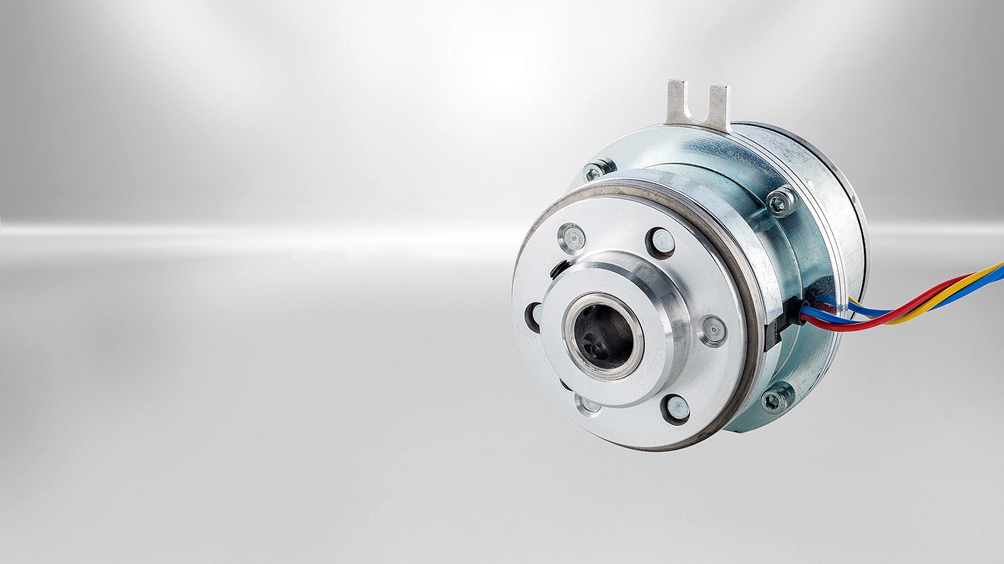

Understanding Electromagnetic Clutches: Electromagnetic clutches are devices that utilize electromagnetism to transfer torque from a driving shaft to a driven shaft. They consist of two main components: an electromagnetic coil and a magnetic armature. When the coil is energized, it generates a magnetic field that attracts the armature, creating a frictional force that allows torque to be transmitted. This enables smooth engagement and disengagement of power between the driving and driven components.

Applications of Electromagnetic Clutches: Electromagnetic clutches find wide-ranging applications in numerous industries, including automotive, robotics, machine tools, printing, packaging, and textile machinery. Some common uses include:

- Automotive Industry: Electromagnetic clutches are employed in automatic transmissions, air conditioning systems, and power steering mechanisms.

- Industrial Machinery: They are utilized in conveyors, printing presses, and textile machines, enabling precise control over speed and motion.

- Robotics: Electromagnetic clutches enable accurate control of robotic arms, allowing for precise positioning and movement.

Benefits of Electromagnetic Clutches:

- Smooth and Efficient Operation: Electromagnetic clutches provide seamless engagement and disengagement, ensuring smooth operation and preventing shock loads.

- Precise Torque Control: These clutches allow for accurate control over torque transmission, facilitating precise speed regulation and preventing overloading.

- Durability and Reliability: Electromagnetic clutches are designed for high-performance applications, offering long service life and reliable operation even in demanding conditions.

- Safety: They contribute to the safety of machinery by providing instant engagement and disengagement, reducing the risk of accidents and minimizing damage to equipment.

- Energy Efficiency: Electromagnetic clutches consume power only when engaged, leading to energy savings and improved overall efficiency.

Electromagnetic Brakes: Similar to electromagnetic clutches, electromagnetic brakes utilize the principles of electromagnetism to control motion. However, their primary function is to stop or hold rotating components. When the electromagnetic coil is energized, it creates a magnetic field that attracts the armature, resulting in frictional force that stops or holds the rotating shaft.

Applications and Advantages of Electromagnetic Brakes:

- Machine Tools: Electromagnetic brakes are used in lathes, milling machines, and drills to provide rapid stopping and precise positioning.

- Elevators and Escalators: These brakes ensure safe and smooth operation of elevators and escalators by holding the platform in place when power is interrupted.

- Wind Turbines: Electromagnetic brakes are utilized to stop or slow down wind turbine blades during maintenance or emergencies.

- Advantages: Electromagnetic brakes offer quick response times, high torque capacity, and precise control over stopping and holding forces. They are also maintenance-free and exhibit long service life.

Conclusion: Electromagnetic clutches and brakes have revolutionized the way motion control is achieved in various industries. By harnessing the power of electromagnetism, these devices provide precise torque control, seamless operation, and enhanced safety. With their broad range of applications and numerous advantages, electromagnetic clutches and brakes continue to play a vital role in modern